|

| |

|

| |

보오크사이트(α-Al2O3) 광물을 고온에서 정련한 고순도, 고경도의 금속산화물로 Al2O3, TiO2와 극소량의 SiO2, Fe2O3 및 기타성분을 함유하며 제조과정에 따라 품질차이가 있으며, 희소성분 함량에 따라 백색, 갈색, 핑크색, 검정색이 있고 용도에 따라 사용된다. |

|

| |

|

|

| 산화알미늄 |

Brown Fused Alumina(A) |

White Fused Alumina(WA) |

| Color |

Dark Brown(갈색) |

White(흰색) |

| 밀도(g/㎤) |

3.97 |

3.9 |

| 가비중 |

2.1~1.7 |

2.1~1.7 |

| 입도형상 |

Angular |

Angular |

| 경도(Moh’s) |

9 |

9.2 |

| Al2O3 |

97~92.5%min (16~220Mesh) |

97~98.5%min (16~220Mesh) |

| TiO2 / Na2O |

1.5~3.8% |

( 0.5~0.8%max ) |

| 자성 |

0.038~0.017max(16~220Mesh) |

- |

|

|

|

|

| |

| - 규격 Size |

|

|

| Grit No |

Micron |

Grit No |

Micron |

| A(WA)#12 |

2000~1700 |

A(WA)#100 |

150~125 |

| A(WA)#16 |

1400~1180 |

A(WA)#120 |

125~106 |

| A(WA)#20 |

1180~1000 |

A(WA)#150 |

106~75 |

| A(WA)#24 |

850~710 |

A(WA)#180 |

90~63 |

| A(WA)#36 |

600~500 |

A(WA)#220 |

75~53 |

| A(WA)#46 |

425~355 |

A(WA)#240 |

75~53 |

| A(WA)#60 |

300~250 |

A(WA)#280 |

63~50 |

| A(WA)#80 |

212~180 |

A(WA)#320 |

50~40 |

|

|

|

|

| |

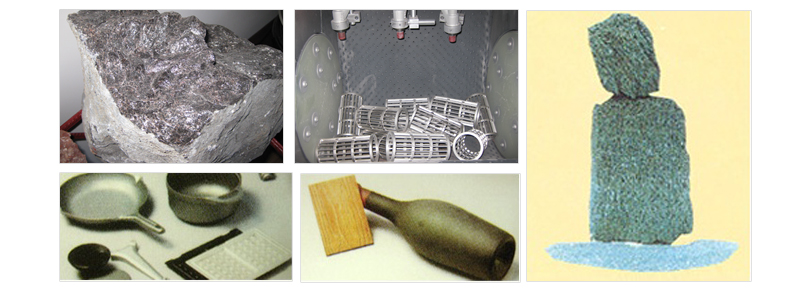

| - 용도 Application |

|

|

| 처리목적 |

피가공품 |

| decoating |

Al, Zn, Copper, Bronze, Stainless, Titanium,Alloy parts.

extrusion, rolling parts- casting, structure parts

casting parts

Glass, wooden, Cristal Ceramic-parts

Glass-plate

|

|

| descaling |

| deburring |

| etching |

| cutting |

|

|

|

|

| |

|

| |

|

|

| 탄화규소(Si-C) |

Black Silicon Carbide (C) |

Green Silicon Carbide (GC) |

| Color |

Black(검정) |

Green(그린) |

| 밀도(g/㎤) |

3. |

3.2 |

| 가비중 |

2.0~1.6 |

2.0~1.6 |

| 입형 |

Angular |

Angular |

| 경도(Moh’s) |

9.5 |

9.5 |

| SiC |

98.5~97.0%min (16~220Mesh) |

99.0~97.5%min(20~240Mesh) |

| F.C |

0.2~0.3%max (16~220Mesh) |

0.20~0.25%max(20~240Mesh) |

| Fe2O3 |

0.6~1.2%max (16~220Mesh) |

0.20~0.70%max(20~240Mesh) |

| 자성 |

0.025~0.012%max (16~220Mesh) |

0.018~0.010max(20~220Mesh) |

|

|

|

|

| |

| - 규격 Size |

|

|

| Grit No |

Micron |

Grit No |

Micron |

| C(GC)#16 |

1400~1180 |

C(GC)#100 |

150~125 |

| C(GC)#20 |

1180~1000 |

C(GC)#120 |

125~106 |

| C(GC)#24 |

850~710 |

C(GC)#150 |

106~75 |

| C(GC)#36 |

600~500 |

C(GC)#180 |

90~63 |

| C(GC)#46 |

425~355 |

C(GC)#220 |

75~53 |

| C(GC)#60 |

300~250 |

C(GC)#240 |

75~53 |

| C(GC)#80 |

212~180 |

C(GC)#280 |

63~50 |

| - |

- |

C(GC)#320 |

50~40 |

|

|

|

|

| |

| - 용도 Application |

|

|

| 처리목적 |

피가공품 |

| cleaning |

Glass, Cristal ,Ceramic,stone-parts

(non-metallic ABRASIVES)

|

|

| descaling |

| deburring |

| etching |

| cutting |

|

|

|

|

| |

|

| |

|

|

| SiO2 |

39.12% |

FeO |

23.89% |

MnO |

0.15% |

MgO |

9.78% |

| Al2O3 |

20.92% |

Fe2O3 |

4.15% |

TiO2 |

0.095% |

CaO |

9.56% |

| 밀도(g/㎤) |

3.97 |

| 가비중 |

2.15 |

| 경도(Moh’s) |

7.64 |

| 용융점 |

1340℃ |

|

|

|

|

| |

| - 규격 Size |

|

|

| Grit No |

Micron |

Grit No |

Micron |

| 10/20 |

2000~850 |

46 |

425~355 |

| 20/40 |

850~425 |

60 |

300~250 |

| 30/60 |

600~250 |

80 |

212~180 |

| 24 |

850~710 |

100 |

150~125 |

| 36 |

600~500 |

120 |

125~106 |

|

|

|

|

| |

| - 용도 Application |

| Descaling --------------------Steel or Stainless Structure Parts |

| |

|

|

| |